AGEMA: Precision starting hole erosion machines made in Germany

September 16, 2024 / 2:55 PM

AGEMA Germany is a medium-sized family business and German manufacturer of start hole drilling machines of the highest precision. With origins in Switzerland under the name AGEMA Swiss, we are now constantly developing our machines in the field of EDM drilling.

Our young and dynamic team lives for customer proximity. With a control system developed in-house and in-house design and development, we offer our customers the option of individual solutions. Furthermore, we can offer our customers high-precision machines made in Germany through our own assembly and production.

We combine the technologies of EDM micro-drilling, starting hole drilling and thread sinking on our machines.

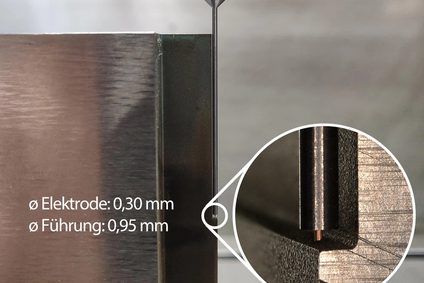

Micro-drilling on the AGEMA machine is extremely reliable. In comparison to hard metal electrodes, inexpensive copper electrodes are used. Micro-drilling is characterized by very low electrode wear. The special generator technology allows a very small spark gap. This means that holes with a final diameter of 0.15 mm can be produced using 0.12 mm electrodes. Our high-precision intermediate guide stabilizes and guides the electrode so that it does not move even at great drilling depths.

Threads and countersinks can be made in hard metal and hardened steel. Furthermore, holes can also be widened and thus highly precise diameters for fits, for example, can be created.

By using oil as a dielectric, we achieve the highest precision and quality in the erosion result. This results in the following advantages for erosive machining and precision start hole erosion on an AGEMA machine:

- small spark gap: an electrode with a larger diameter can be used, which significantly improves the accuracy of small drill holes

- very high surface quality

- no microcracks

- no corrosion

- no leaching of cobalt

- enables countersinking and drilling on one machine

The machines are offered in two different sizes, the AS 320 and the AS 430. Various automation options can be integrated. For example, a 6-way electrode changer or a 40-way electrode changer are available. Multi axes in different designs are also supported.

We are happy to offer a free test machining of your components to convince you of our quality.

Web:

https://www.agema-germany.de/

https://www.youtube.com/channel/UCSRLqe9HxFCHlNaBtjxTmsQ

https://www.linkedin.com/company/agema-germany-gmbh

Company is exhibiting at the ALFLETH Engineering AG stand, hall P, stand no. 50