BLM GROUP: Expert in manufacturing systems for metal tube and sheet metal

August 6, 2024 / 9:35 AM

BLM GROUP specializes in manufacturing systems for metal tube and sheet metal processing that are widely configurable, including automation options even after machine purchase. The systems produced by BLM GROUP are used in all areas where sheet metal or metal tube is utilized, and laser cutting is a particularly beneficial solution when processing light and heavy metal carpentry for the realization of steel constructions in both structural and interior and exterior furnishing elements. Precision and quality paired with the benefits of laser machining translate into a clear economic advantage because of the ability to greatly simplify and speed up the commissioning phase of a metal structure while reducing costs.

At MSV BLM GROUP exhibits LT7 and ELECT, Hall B, booth 30.

The solution for tube laser cutting

LT7

The LT7 is a cutting-edge Lasertube system capable of processing tubes ranging from 12 to 152 mm in diameter and up to 23 kg/m in weight, guaranteeing exceptional cutting performance. From the smallest to the largest diameter, every adjustment is fully automated and even sections with “L”, “U” and other open profiles and flat bars are standard jobs, all processed in a fully automatic mode. The laser source allows great flexibility of thicknesses and materials, from 12 mm of mild steel to 4 mm of brass. 3D processing completes the framework of an extremely flexible system able to manage the widest array of applications. The LT7 is an unparalleled, state-of-the-art solution designed to optimize productivity, quality, precision, flexibility, automation, and ease of use.

Equipped within the exhibited LT7 there is the automatic inserting unit for threaded rivets on thin laser-cut tubes. This additional device simplifies the creation of tubular components for metal frames and structures.

The solutions for tube bending

ELECT

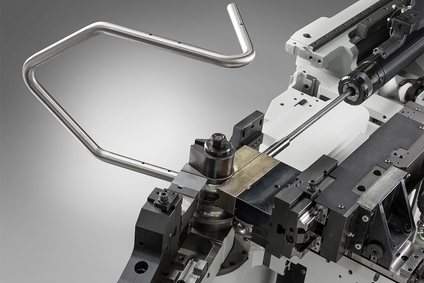

All-Electric tube bending machine, configurable for right or left-hand bending directions, equipped with cutting-edge 3D visual graphic programming VGPNext. The sturdy construction of the ELECT ensures unwavering stability, providing impeccable precision and consistency in part production. Its adaptability caters to batches of any scale within a multitude of industrial domains, ensuring ease of use and exceptional performance standards.

Web and social networks:

www.blmgroup.com

www.blog.blmgroup.com

www.blmgroup.com/it/inspired-for-tube

www.facebook.com/BLMGROUP

www.youtube.com/BLMGROUPchannel

www.linkedin.com/company/blmgroup