data Partner: supply and implementation of information and control technologies

July 22, 2024 / 1:10 PM

dataPartner is a Czech company based in České Budějovice, which has been operating on the market for more than 25 years in the field of supply and implementation of information and control technologies. It produces the MES PATRIOT production information system for production and maintenance management, automates machines and production lines. It also supplies software components for the creation of control units and machine controllers.

DataPartner is a regular exhibitor at the International Engineering Fair in Brno. Visitors can get acquainted with the company's product portfolio in Hall F at stand 16 and also at the Digital Factory area.

The focus of dataPartner's exhibits at both locations will be the presentation of means for digitizing production, both in the field of machine automation and the MES production information system.

MES PATRIOT®

Management and competent employees of manufacturing companies will certainly be interested in the MES manufacturing information system PATRIOT®.

In a personal meeting with dataPartner representatives, you can get information, experience and recommendations from its implementation in various manufacturing companies. When implementing MES PATRIOT® in plants, it is possible to proceed in stages, according to priorities, and gradually expand the implementation without the need to replace the previous version. MES PATRIOT® is scalable, its modules can be added and individual functions can be extended:

- Production planning - operational and capacity planning with the possibility of extending it with third-party APS. Supports easy integration with ERP.

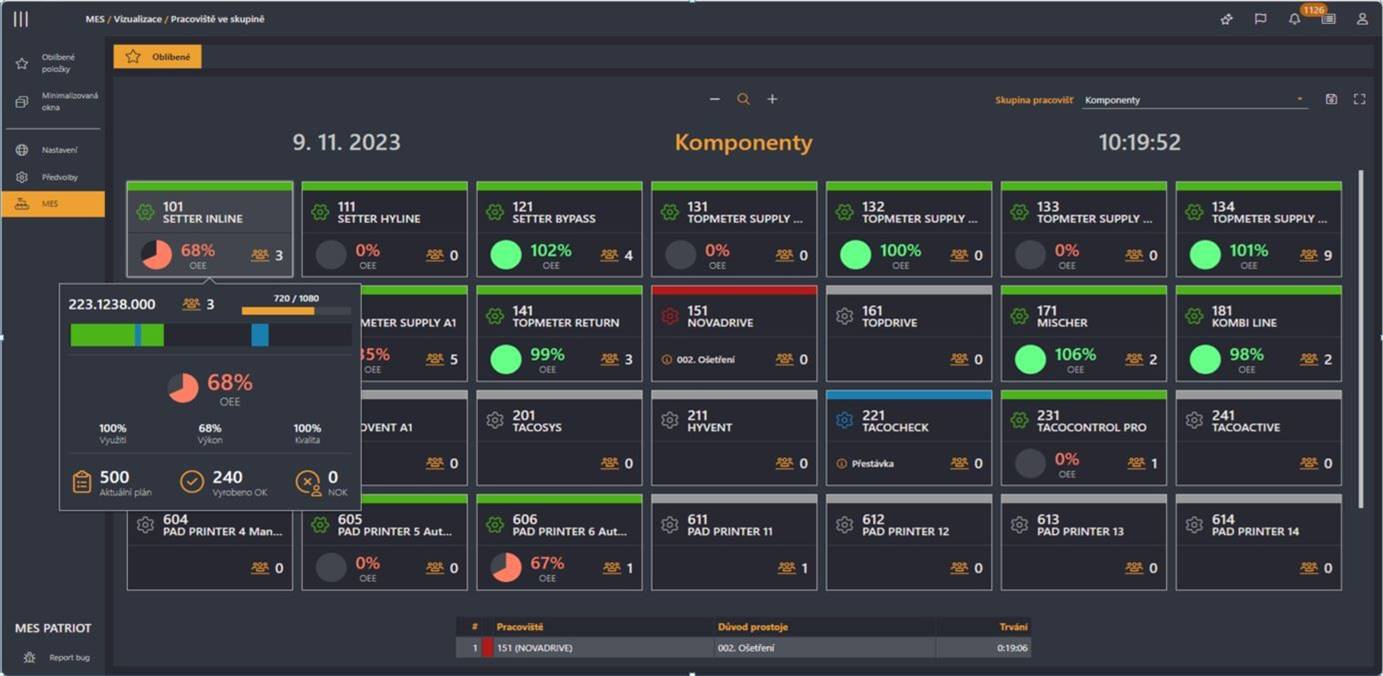

Production monitoring and visualisation - collect, analyse and record process data from production and provide feedback to optimise plans. Input part tracking and production lead tracking provides bi-directional production traceability, corrective action effectiveness tracking is available in the QI module. Examples of reports, production kiosks, and visualization of the current state of ANDON machines can be seen. Also, a rapid response system (FRS) for recording and efficient troubleshooting of production and monitoring of machine utilization (OEE coefficients, TEEP, KPIs, ...), employee performance, etc.

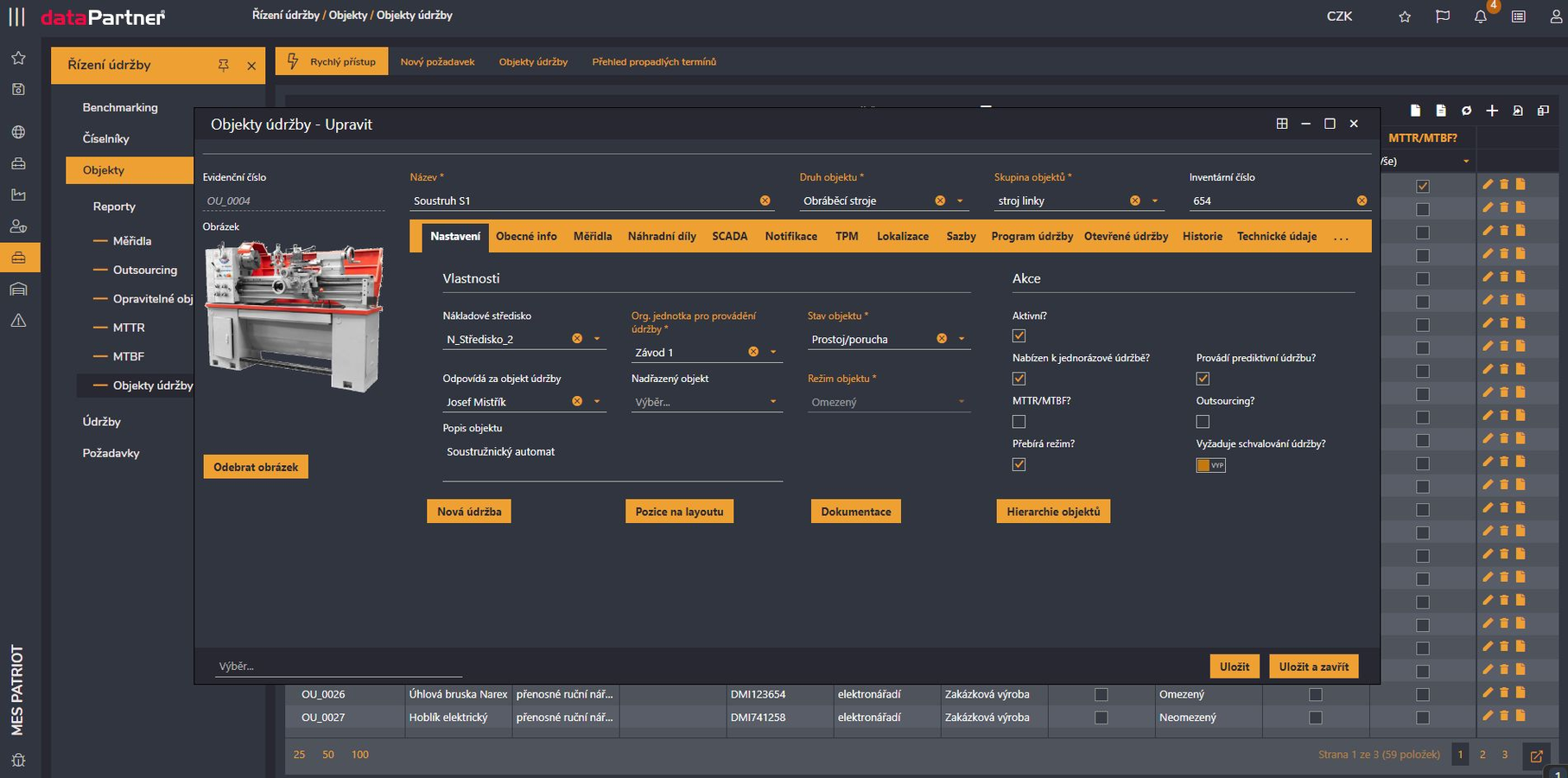

Maintenance management - production and non-production assets, technological units, individual machines and production equipment down to individual parts and gauges. It supports the renewal of objects using all maintenance strategies: corrective, preventive, diagnostic and predictive. Easy availability of electronic documentation, including records of the cause of failures and measures taken. Maintenance requests are entered manually, can be generated automatically by monitoring the current status data from the SCADA system or can arise from specific requests from the FRS. Of course, the maintenance management system can be linked to existing enterprise systems (e.g. ERP, MES from other manufacturers). The system uses terminology in accordance with current standards, which unifies terms and facilitates communication between professionals. As a basic version, pilot project or economical solution, the PATRIOT CRYSTAL maintenance management system can be used, which addresses the basic types of maintenance: corrective and preventive, and enables a simple and seamless transition to the full version of the PATRIOT 3.0 maintenance management information system later, without the need to migrate and rewrite data.

KINGSTAR

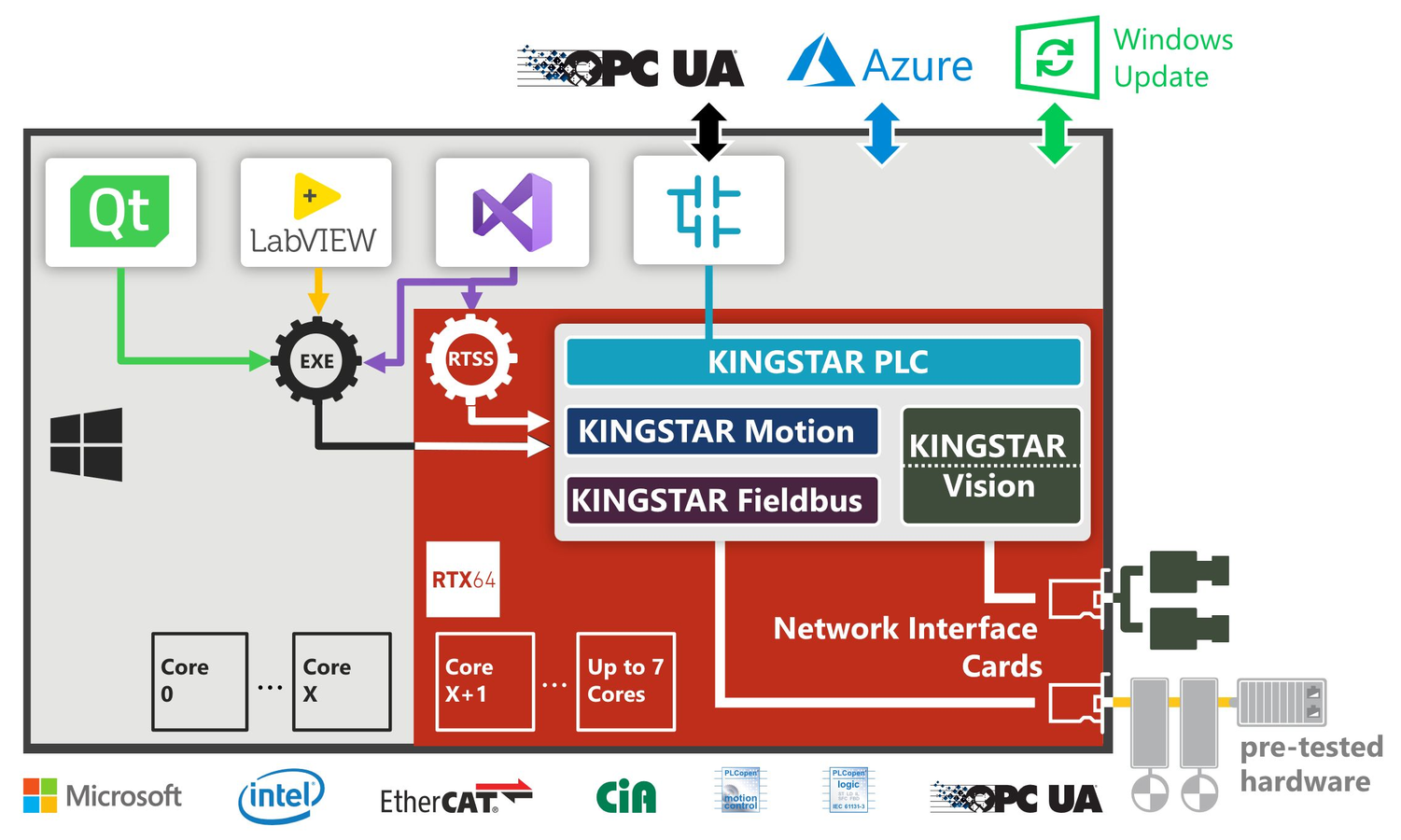

The KINGSTAR software platform from the American company IntervalZero is designed for designers and developers of machine control units. It is based on the use of established standards, where independence from a specific subcontractor is often a question of growth or decline of a company in the market. KINGSTAR for creating machine and robot drivers and control applications is an open platform, representing a technological breakthrough in the technology for creating flexible controllers. Therefore, it is also suitable for the creation of modular machines. It allows you to choose hardware from different manufacturers and avoid possible unavailability. With the KINGSTAR platform, machine controllers are created on a standard general-purpose computer such as an IPC with MS Windows, which operates in fixed real-time with the RTX64 add-on. Thanks to openness and standardization, developers are not dependent on specific brands of HW components and can choose from a wide range of standardized alternatives.

The use of KINGSTAR will enable the goals of today's developers and controllers to be met: To create intelligent and flexible machine controllers according to market requirements in a timely and cost-competitive manner. KINGSTAR consists of five components:

If you have your own team of control application developers, dataPartner offers free consultation and advice for purchasing a KINGSTAR license or Windows RTX64 add-on for real-time work. If you do not have a software development team or your team does not have the necessary capacity, we offer cooperation. Together you can create modern and cost-effective solutions, especially for the implementation of robotic, testing, sorting and other machines and systems. Using KINGSTAR and IPC-based hardware, create time-accurate, highly reliable and easy-to-maintain machine control applications in a short time. A demonstration of dataPartner's work can be seen at stand F16, where the mechatronic model "Slip" will be running.

Take the opportunity to meet in person at the show and come and discuss your projects, needs and requirements with dataPartner representatives.

You can schedule a meeting on a specific date and time in the Contact-Contract application or email obchod@datapartner.cz or call +420 380 420 140, +420 724 257 799.