FICEP: World leader in the design and production of automatic systems for the steel fabrication industry

August 16, 2024 / 9:32 AM

With nearly a century of experience, FICEP has become the world's leading producer of automated systems for structural steel and plate fabrication, and a prominent manufacturer of forging equipment. FICEP success arises from over 90 years of continuous innovation, leading to a diverse product range that has penetrated global markets through numerous subsidiaries.

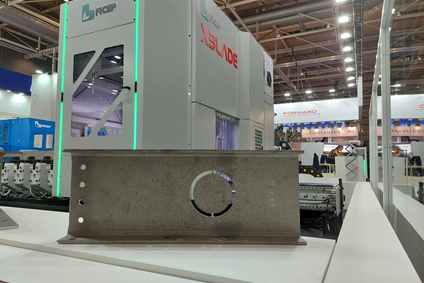

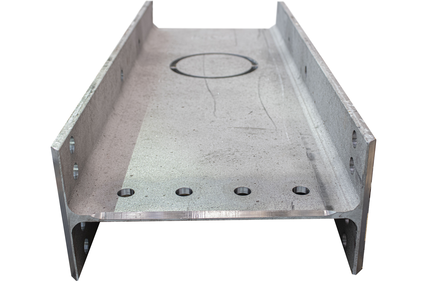

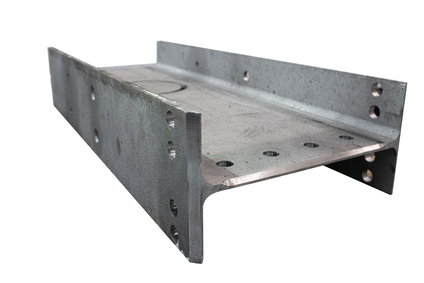

A COMPACT AND AUTOMATED ALL-IN-ONE SOLUTION FOR MACHINING AND CUTTING PROFILES

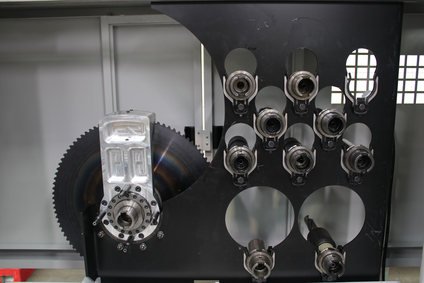

The new XBLADE is a compact, automated all-in-one solution for drilling, tapping, milling and cutting. Designed to meet the flexibility needs of small and medium-sized steel constructors, this machine combines all the necessary technologies in a single module, reducing the footprint by 30% compared to traditional systems. The key element of XBLADE is the bi-rotary head that can use both drilling and milling tools and cutting discs, performing all operations with a single workpiece positioning. The compact and rigid structure allows you to process small parts dimensions, with a minimum capacity up to a maximum of 305x305 mm in the case of machining on three sides. If, on the other hand, the operations are processed on only one side of the profile, you can operate up to 460x460 mm. As concerns the structural part, the machine has been designed with a C-frame moving column. Along the longitudinal X axis, movements are achieved by a rack-and-pinion system, while along the Y and Z axes, the screw balls command the systems for optimum performance, ensuring precision and rigidity. The 5-axis head, designed by FICEP, without a mechanical reduction unit, is driven by a 32 kW direct-drive spindle with a torque of 360 Nm, capable of performing operations on all sides of the profile.

Integrated tool storage

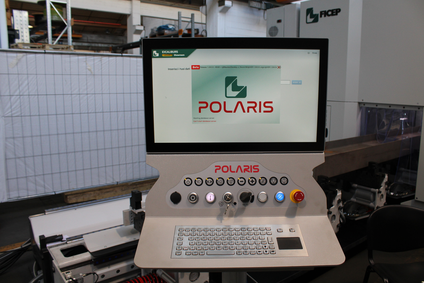

The flexibility of the XBLADE is amplified by the integrated tool storage on the main unit, inside the cab, which moves together with the head and allows tools to be changed extremely quickly. In addition, during disc cutting operation the blade guide system performs a vibration dampening function to improve the quality of the operation and increase tool life. Thanks to the cabin that isolates the working area and allows the containment of chips, which are collected by special tanks, the machine can operate without any safety problems. At the back of the cabin are positioned the cooling system for the high-power spindle and the electrical cabinet. XBLADE is operated via numerical control with Polaris HMI.

In conclusion, XBLADE is a significant innovation and evolution of the well known EXCALIBUR, the automatic CNC single spindle drilling line for sections. In fact, the new cutting-edge machine incorporates all the EXCALIBUR features with an advanced design, introducing cutting operations and 5-axis machining within the same work cell, making it truly unique.

Web and social media:

https://ficepgroup.com/en/

https://it.linkedin.com/company/ficep

https://www.instagram.com/ficepspa

https://www.youtube.com/channel/UC4RbMphLv8onjedunGO0M_Q

https://www.facebook.com/ficepspa/

https://twitter.com/FICEP